leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

Steel pipes can be produced by steel pipe making machine, which typically involves the following steps:

The primary raw material for steel pipes is steel coils. Various types of steel can be used, including carbon steel, alloy steel, or stainless steel. Purchase or cut steel strips of corresponding size according to the diameter of the steel pipe. (cut steel strips, you can buy the steel coil slitting machine)

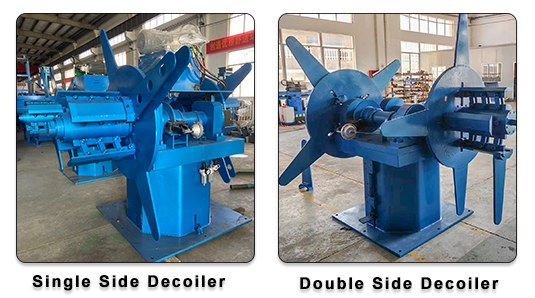

The process begins with uncoiling steel coils or strips that serve as the raw material for the pipes. There are two kinds of decoiler, one is double side decoiler, another is single side decoiler.

Its function is to store steel strips to ensure uninterrupted production. There are two kinds of accumulator, vertical type and horizontal cage type accumulator. We will recommend suitable accumulator based on customer production specifications.

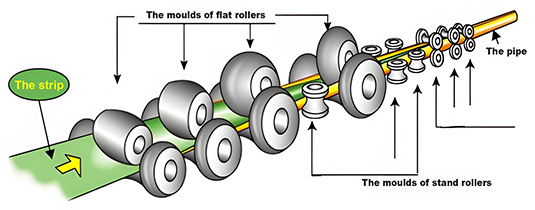

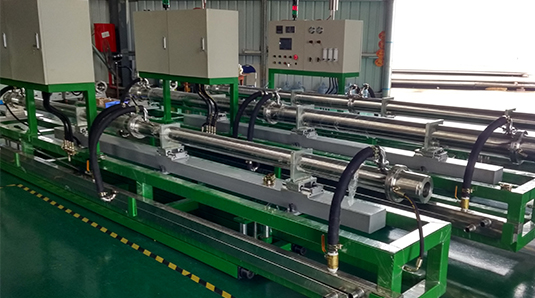

There are various methods for forming pipes from the steel coils. The most common method is welded pipe manufacturing: Welded pipes are made from steel strips. The steel is rolled into a cylindrical shape and welded longitudinally. This can be done using different welding techniques such as electric resistance welding (ERW), tig arc welding, or high-frequency welding (HF).

After forming, the pipes may undergo heat treatment processes such as annealing, normalizing, or quenching and tempering to improve their mechanical properties and remove internal stresses.(Optional)

Once the pipes are formed and heat-treated, they undergo finishing processes such as straightening, cutting, and sizing to meet the required dimensions and surface quality standards.

The finished pipes are inspected one final time to ensure they meet all quality standards. They are then bundled, labeled, and prepared for shipping to customers.

This is a general overview of the steel pipe manufacturing process, and variations may exist depending on factors such as the type of steel, pipe dimensions, and manufacturing technology used.

We have two kinds of pipe making machine, one is high frequency erw pipe making machine, another is tig welding pipe making machine. Tell us your needs and we will recommend the appropriate pipe making machine.

KINGTECH TUBE MILL CO. LTD

Email: fsyxh4@tubemakingmachine.com

Whatsapp: +86 13336483052