leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

Choosing the right steel tube mill machine is essential for achieving efficiency, quality, and profitability in tube manufacturing. Here’s a detailed guide to help you choose the most suitable steel tube mill machine:

Tube Dimensions: Determine the range of tube diameters, wall thicknesses, and lengths you need to produce.

Tube Shape: Consider whether you need to produce round, square, or rectangular tubes.

Material Type: Identify the material you’ll be processing (carbon steel, stainless steel, galvanized steel, etc.).

Production Volume: Understand your required output (tons or meters per hour/day) to ensure the machine can handle your production needs.

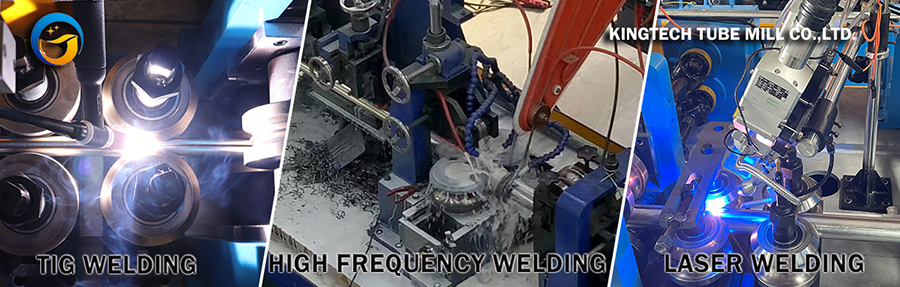

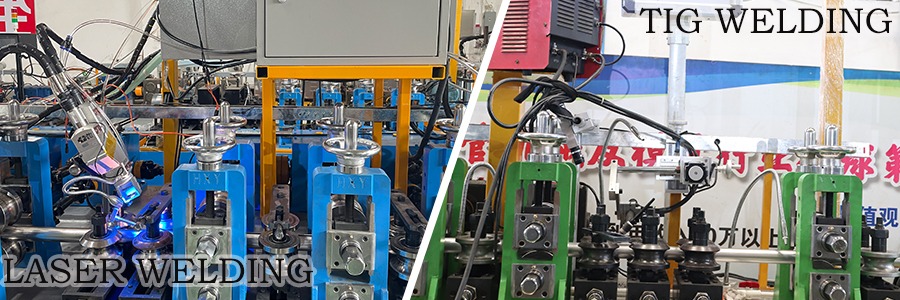

TIG (Tungsten Inert Gas Welding) tube mill :

TIG welding provides high quality welds and can weld stainless steel.

Laser Welding tube mill :

Laser welding machine is a high-precision welding process that uses a focused laser beam to melt and join materials together,its ability to create strong, high-quality welds with minimal heat-affected zones.

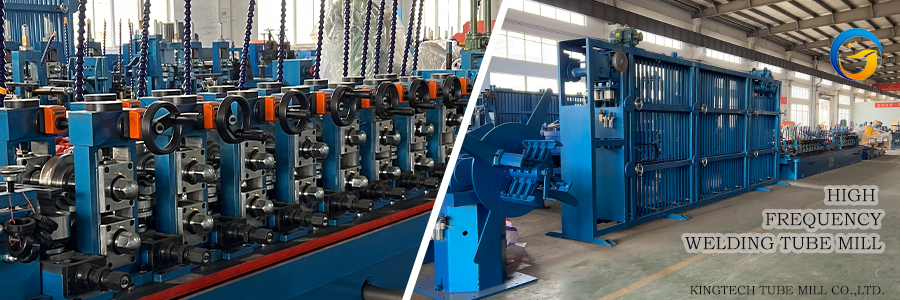

High-Frequency (HF) welding tube mill:

Used for producing high-quality tubes with uniform welds, can mass production of high-quality steel tubes,suitable for industries like energy and heavy machinery,such as construction, automotive, and pipelines.

If you want to produce stainless steel tube, you can choose laser welding pipe making machine or tig welding pipe making machine. Why is it recommended? Because argon arc welding and laser welding have high quality and precise control when welding stainless steel pipes. Of course, the price of laser welding pipe making machine is higher than that of argon arc welding pipe making machine. Because laser welding technology has high precision, clean seams, faster welding time, improved efficiency and cost savings of electric welding methods.

If you want to produce carbon steel tube / galvanized steel tube but the monthly output is less than 100 tons, you can choose laser welding pipe making machine or tig welding pipe making machine.

If you want to produce carbon steel tube / galvanized steel tube and the monthly output exceeds 200 tons, you can choose high frequency erw tube mill. Because the production speed of erw tube mill is 20-120m/min.

Of course, if you want a complete set of steel pipe production line, you also need to know the pipe diameter and thickness, as well as the purpose of the finished pipe.

Knowing the pipe diameter and thickness is for matching the mold. One specification one set of molds.

Knowing the purpose of the tube is to determine the quality requirements of the tube and whether it needs to be equipped with bead rolling machine and bright annealing machine.

So, please tell us your requirement ( material, diameter and thickness, application, monthly output) that we can recommend you the suitable pipe manufacturing machine.

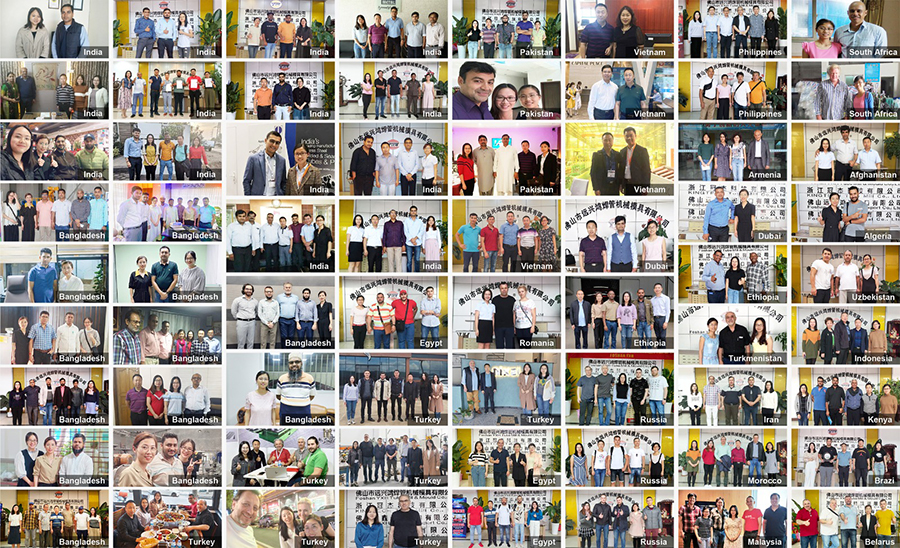

We have manufacturer tube mill, mould since 2001 years.Until now, we served more than 2000 clients in 103 countries, therefore we have rich production experience and export experience. We are pretty sure that we will be your right choice.

In a word, if you interested in steel tube mill , please don't be hesitated to contact us.

KINGTECH TUBE MILL CO. LTD.

Email: fsyxh4@tubemakingmachine.com

Whatsapp: +86 13336483052