leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

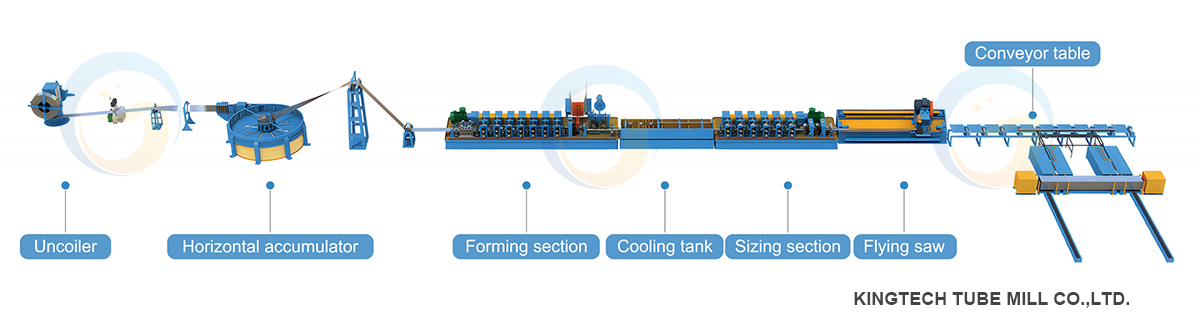

Steel tube mill converts metal strips into tubes through a process involving uncoiling, roll forming, welding, sizing, and cutting. The steel coil strip is progressively formed into a tube shape, with high-frequency welding used to join the edges. The steel tube is then sized for precision and cut to length, producing welded steel tubes for various applications.

Steel pipe making machine converts metal strips into tubes through a series of processing steps such as forming, welding, sizing, and cutting. The fundamental principle involves mechanical and thermal forces to bend and join the metal into a tubular shape.

Strip coil - Uncoiler - Shear and butt welder - Accumulator - Levelling - Forming - Welding - External burr removing - Cooling - Sizing - Straightening - Cut size - Unloaing.

Uncoilr and Accumulator: Metal coil is loaded onto the uncoiler, and the strip is fed through the accumulator to ensure the continuous production,than feed into the forming section.

Forming: The strip is gradually formed into a tubular shape through a series of forming rolls.

Welding: The edges of the formed strip are welded together. High-frequency welding is often used due to its speed and quality, ensuring a strong and uniform weld seam.

Sizing and Straightening: The welded pipe goes through sizing rolls to achieve the final dimensions and to ensure straightness.

Cutting and Collection: The continuous pipe is cut into specified lengths and then collected by winding into coils or stacking in bundles.

We can also fully understand the working principle of the pipe making machine through the video.

Steel tube mill video link: https://www.youtube.com/watch?v=ZXc4Yqvxbrw

If you looking for steel tube mill, please contact us.

Email: fsyxh4@tubemakingmachine.com

Whatsapp: +86 13336483052