leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

| Tube and pipe mill machine product parameters | |||||

| Machine Model | Pipe Size | Pipe Thickness | Production Speed (m/min) | ||

| Round(mm) | Square(mm) | Round(mm) | Square(mm) | ||

| HF20 | 8 - 32 | 10*10-25*25 | 0.4-1.2 | 0.4-1.0 | 20-100 |

| HF28 | 12.7 - 50.8 | 10*10-40*40 | 0.3-1.8 | 0.3-1.2 | 20-100 |

| HF32 | 15 - 63.8 | 10*10-50*50 | 0.5-2.5 | 0.5-2.0 | 20-100 |

| HF50 | 19 - 76 | 15*15-60*60 | 0.8-3.25 | 0.8-2.5 | 20-100 |

| HF60 | 25.4 - 76 | 20*20-60*60 | 0.8-3.5 | 0.8-3.0 | 20-80 |

| HF76 | 32 - 102 | 25*25-80*80 | 1.0-3.5 | 1.0-3.0 | 20-70 |

| HF89 | 48 - 114 | 40*40-90*90 | 1.2-4.0 | 1.2-3.5 | 20-70 |

| HF125 | 60 - 127 | 50*50-100*100 | 1.4-5.0 | 1.4-4.5 | 20-60 |

| HF165 | 76 - 165 | 60*60-125*125 | 1.8-6.0 | 1.8-5.5 | 20-50 |

| HF219 | 114 - 219 | 90*90-170*170 | 2.5-6.0 | 2.5-6.0 | 20-40 |

| HF325 | 165 - 325 | 125*125- 250*250 | 3.0-8.0 | 3.0-7.0 | 10-40 |

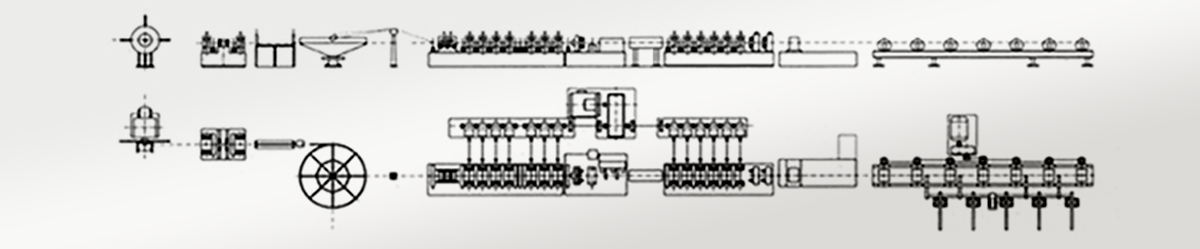

Strip coil - Uncoiler - Shear and butt welder - Accumulator - Levelling - Forming - Welding - External burr removing - Cooling - Sizing - Straightening - Cutting - Packing

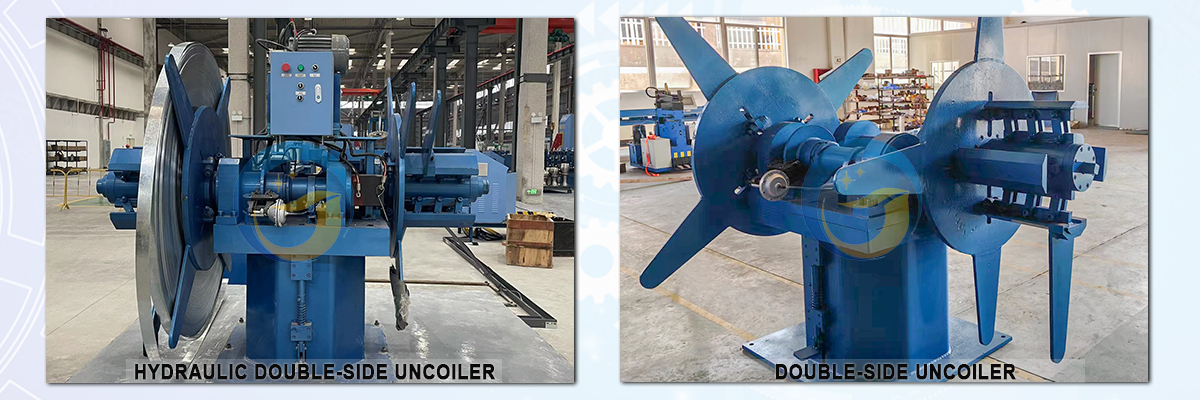

1. Raw Material Uncoiler

It’s used to support the steel strip roll and feed raw material for the production line.

2.Vertical material accumulator

It’s used to store and feed raw materials for forming machine so that the machine can work continuously.

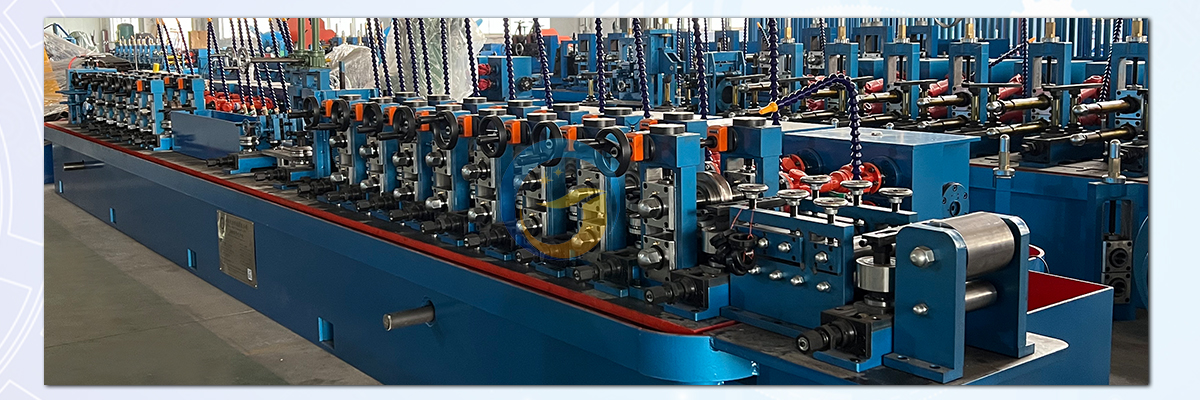

3. Forming and Sizing Machine

It’s the main equipment of the production line. Rollers can make steel strip form into pipes of variety shapes. It consists of forming part , welding part and sizing part.

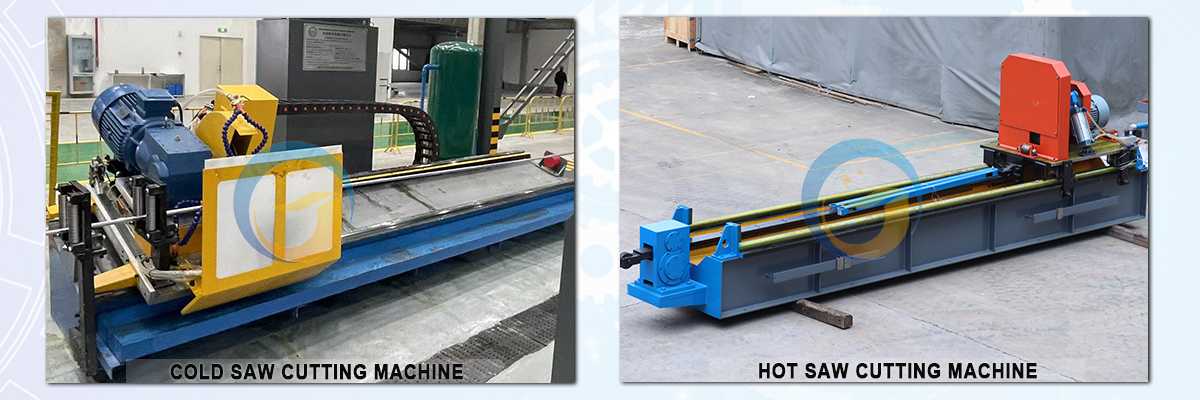

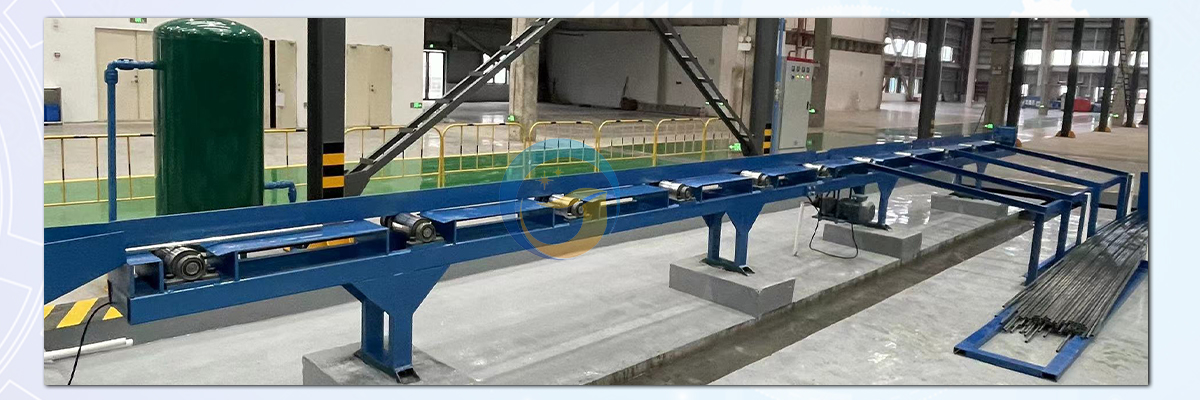

4. Flying cutting saw

With the high precision control system and quick reaction of mechanical system, the computerized cutting saw has reliable synchronization performance and high precision cutting length.

5. Automatic pipe unloading platform

It is an unloading platform of pipes cut by computerized saw. After the pipes falling down, workers can quickly check the quality and package them for preparation of transportation.

6. High frequency induction appliances

6. High frequency induction appliances

Using the current skin effect and proximity effect of high frequency to make both edges of the material rapidly heated to soldering temperature and then weld them together. Using computer to monitor the process can provide the machine with reliable quality.

The finished tubes produced by high frequency tube mahcine are widely used in construction, automobiles, street lamps, furniture, air conditioners, refrigerators, home (clothes hangers, mops), electric vehicles and other vehicles, decorative pipes, threading pipes, oil pipes, shelf pipes and other fields.

Prev : High Frequency Welding Ms Pipe Production Line

Next : none