leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

| Tube and pipe making machine product parameters | |||||

| Machine Model | Round Pipe Diameter(mm) | Round Pipe Thickness(mm) | Square Pipe Diameter(mm) | Square Pipe Thickness(mm) | Installation Size (L*W) (m) |

| HF20 | 8 - 32 | 0.4 - 1.2 | 25 x 25 | 0.4 - 1.0 | 5 * 30 |

| HF28 | 12.7 - 50.8 | 0.4 - 1.8 | 40 x 40 | 0.4 - 1.2 | 5 * 35 |

| HF32 | 15 - 63.5 | 0.5 - 2.5 | 50 x 50 | 0.5 - 2.0 | 5 * 38 |

| HF50 | 19 - 76 | 0.8 - 3.25 | 60 x 60 | 0.8 - 2.5 | 6 * 45 |

| HF60 | 25.4 - 76 | 0.8 - 3.5 | 60 x 60 | 0.8 - 3.0 | 7 * 45 |

| HF76 | 32 - 102 | 1.0 - 3.5 | 80 x 80 | 1.0 - 3.0 | 7.5 * 50 |

| HF89 | 48 - 114 | 1.2 - 4.0 | 90 x 90 | 1.2 - 3.5 | 8 * 65 |

| HF125 | 60 - 127 | 1.4 - 5.0 | 100 x 100 | 1.4 - 4.5 | 8 * 65 |

| HF165 | 76 - 165 | 1.8 - 6.0 | 125 x 125 | 1.8 - 5.5 | 9 * 75 |

| HF219 | 114 - 219 | 2.5 - 6.0 | 170 x 170 | 2.5 - 6.0 | 10 * 85 |

| HF325 | 165 - 325 | 3.0 - 8.0 | 250 x 250 | 3.0 - 7.0 | 12 * 85 |

| Machine Configuration | 1.double side uncoiler 2.steel strip cutter 3.vertical type material accumulator 4.forming and sizing machine 5.pipe cutting saw(cold cutting or friction cutting) 6.pipe unloading platform 7.rolling molds 8.high frequency appliances | ||||

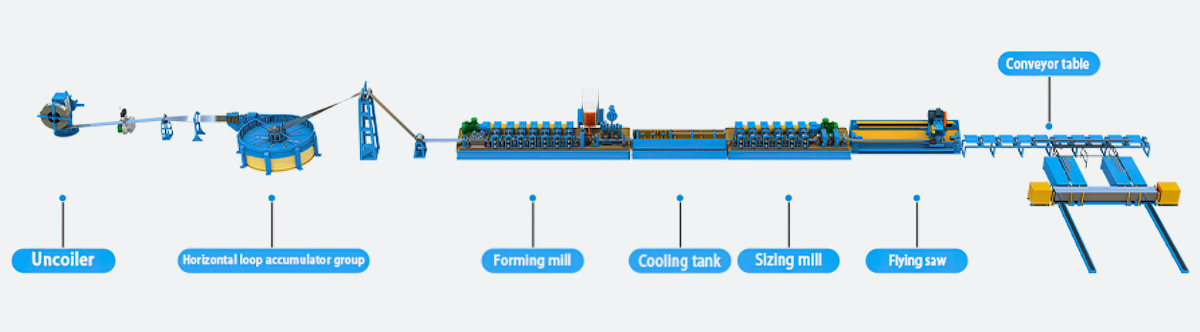

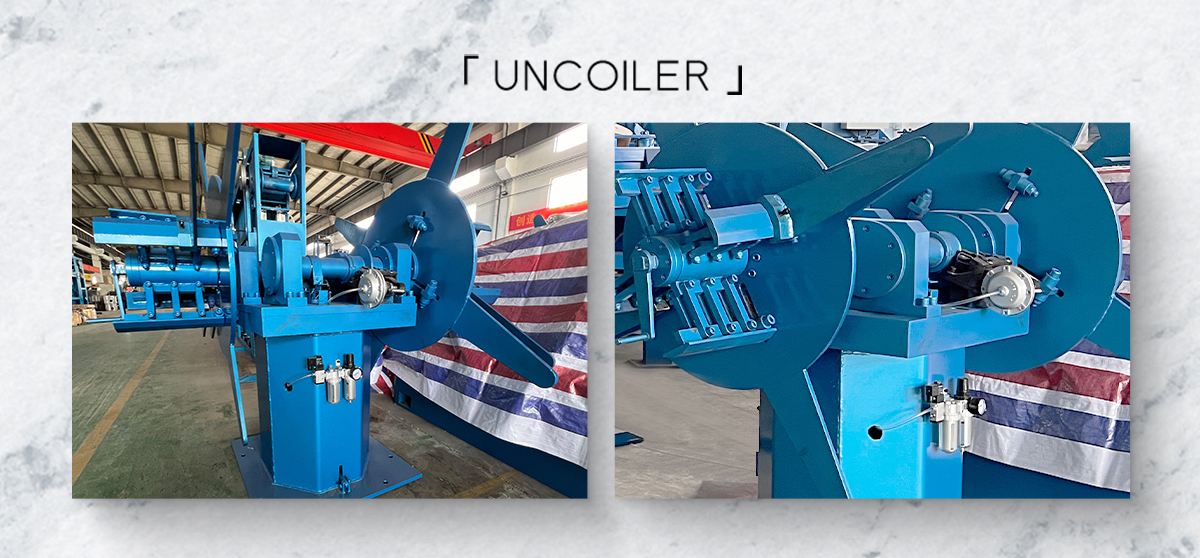

1. Uncoiler: Place the steel strip on the uncoiler and transport it to the forming section.

2. Accumulator for storing steel strips to ensure uninterrupted production. According to the customer's production specifications, the corresponding accumulator will be recommended.

3. Cooling Tank: Because being in a high temperature state after welding can easily cause the pipe to deform, water cooling can prevent the pipe from deforming due to high temperature.

4. Sizing Mill: After welding, the pipe passes through a series of sizing rolls within the roll set. These rolls help shape the pipe to its final dimensions, ensuring uniformity in diameter and thickness.

5. Cutting: Once the pipe has been formed and sized, it is cut to the desired length. This can be done using various cutting methods, such as sawing or shearing, depending on the specific requirements of the application.

6. Run out of table: the steel pipe is collected here after cutting.

Prev : ERW High Frequency Welding Pipe Manufacturing Machine

Next : none