leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

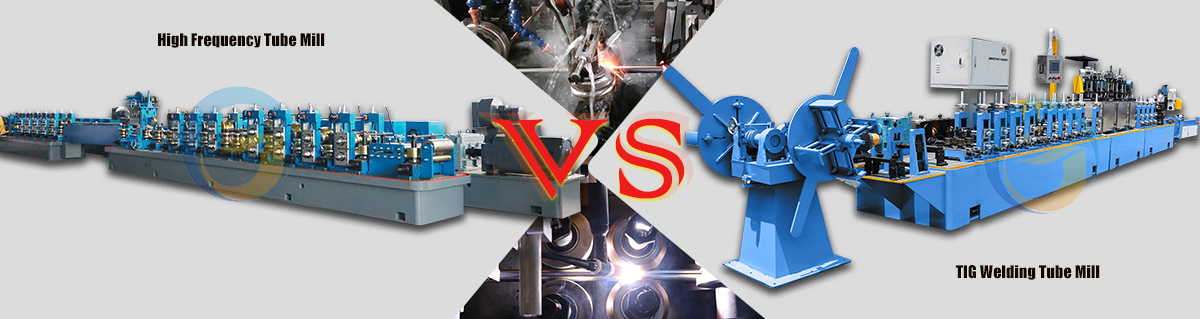

Welding tube mill equipment plays a crucial role in manufacturing, and both high-frequency welded tube mills and TIG welded tube mills are widely used in various industries. These two types of welding tube mill machines have distinct characteristics in terms of working principles, performance, and applications. This article provides a detailed comparison to help companies choose the right welding tube mill equipment based on their production needs.

High-frequency welding machines use high-frequency electrical currents to heat the edges of the tube. The tube edges are then pressed together using rollers to form a weld. This method does not require filler material, and the welding process is fast, making it ideal for continuous production.

The Tungsten Inert Gas (TIG) welding process uses an electric arc as a heat source, with inert gas (argon) protecting the weld pool. Filler material can be added if required. TIG welding provides precise control over the heat input and is suitable for high-precision and high-quality welding.

Performance Indicator | High-Frequency Welded Tube Mill | TIG Welded Tube Mill |

Welding Speed | Fast (up to 120 meters per minute) | Slow (0.5 - 20 meters per minute) |

Weld Quality | Suitable for standard precision requirements, with a typical weld appearance | High-quality, aesthetic welds, ideal for precise work |

Heat Affected Zone | Smaller heat-affected zone, but may have some metallurgical defects in the weld | Precise heat control, smaller heat-affected zone, stable quality |

Material Range | Carbon steel, stainless steel, low-alloy steel, etc. | Stainless steel, aluminum alloys, copper, etc. |

Production Cost | Lower cost, suitable for large-scale production | Higher cost, suited for small-batch, high-value products |

Automation Level | High automation, suitable for mass production lines | Moderate automation, often requires more manual input |

a.Mass production of construction pipes, automotive exhaust pipes, and other common welded products.

b.High-speed welding is needed for products like oil pipelines, water pipes, and structural pipes.

c.Suitable for products with lower aesthetic and precision requirements.

a.Applications where high-quality welding is required, such as in food-grade stainless steel tubes, medical equipment, etc.

b.Ideal for welding complex components or custom-shaped parts that require precise control.

c.Small-batch production or research and development of new products.

a.High-frequency welded tube mills are ideal for high-volume mass production, particularly in fast welding environments.

b.TIG welded tube mills are better suited for small-batch, high-precision production or research applications.

a.High-frequency welded tube mills are better for standard materials like carbon steel and galvanized steel.

b.TIG welded tube mills excel at welding high-end materials such as stainless steel(201,304,316), titanium.

a.The high-frequency pipe welding machine has a high investment cost, but due to its high production efficiency and low operating cost, it is suitable for enterprises pursuing high cost performance.

b.The argon arc pipe welding machine has a low initial investment, but the operating cost is relatively high, so it is suitable for high value-added products.

Both high-frequency welded tube mills and TIG welded tube mills have their own advantages. The former focuses on efficiency and cost-effectiveness, making it suitable for mass production. The latter emphasizes quality and precision, making it ideal for high-end manufacturing. Companies should carefully evaluate their production needs, material types, and budget to choose the best welding tube mill equipment that balances production efficiency and product quality.