leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

1.Introduction to ERW Pipes

ERW pipes, also known as Electric Resistance Welded pipes, are a type of steel pipes that are manufactured using the process of high-frequency induction welding. These pipes are widely used in various industries due to their strength, durability, and cost-effectiveness.

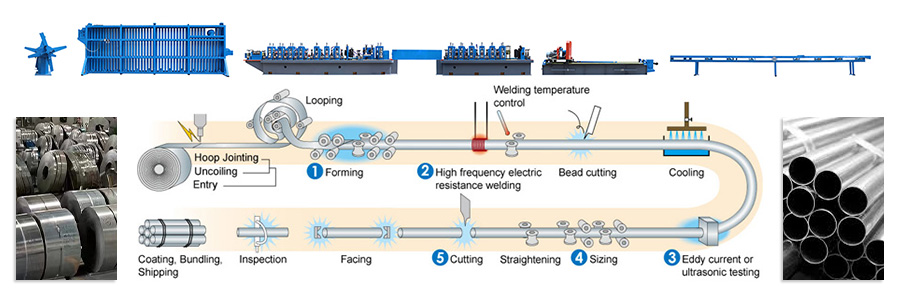

2.Understanding the Manufacturing Process of ERW Pipes

ERW pipes are usually made by erw pipe manufacturing machine.The manufacturing of ERW pipes begins with the coil sheet of steel , the steel belt is fed into a series of forming rolls that gradually shape it into a cylindrical shape with an open seam, resembling a tube. And then will be heated and fused together using high-frequency electric current, forming a strong joint. To facilitate the welding process, the edges of the welded seam must be properly prepared, ensuring a clean and smooth weld. After that the tube will be fed through the forming rolls, which apply pressure to shape it into the desired tubular form.

3.Recognizing the Benefits of ERW Pipes

ERW pipes, also known as Electric Resistance Welded pipes, are widely used in various industries for numerous applications. These pipes possess several benefits, such as

3. A.High Strength and Durability: ERW pipes are manufactured using high-quality steel, which imparts them with exceptional strength and durability. The welding process used in their production ensures a strong bond between the edges of the steel strip, making the pipes capable of withstanding high-pressure environments.

3. B.Cost-Effective: The manufacturing process is relatively simple and requires fewer resources compared to other types of pipes. Additionally, the availability of raw materials at a lower cost contributes to their economical nature.

3.C.Versatility in Applications: ERW pipes find extensive usage across various industries due to their versatility. They are commonly employed in water supply systems, agriculture, gas pipelines, mechanical and structural applications, and more.

3.D. Excellent Dimensional Accuracy: One of the key advantages of ERW pipes lies in their exceptional dimensional accuracy. The pipes are manufactured with precise measurements, ensuring uniformity in size and shape.

3.E. Environmentally Friendly: The absence of any filler materials or chemical additives during welding reduces the environmental impact. Moreover, the simplicity of manufacturing and the recyclability of steel contribute to their eco-friendly reputation.

In conclusion, With high strength, cost-effectiveness, versatility in applications, excellent dimensional accuracy, and environmental friendliness, ERW pipes emerge as a reliable choice for numerous piping requirements.

4.The Various Applications of ERW Pipes

4.A. Line Pipes: ERW pipes are championed in the oil and gas sector. ERW pipelines are resistant to corrosion caused by petroleum by-products, and the ability of ERW pipelines to handle high-pressure environments plays an important role in the transportation and distribution of oil and gas products.

4.B. Structural Tubes: In the realm of construction, ERW structural tubes form the skeletal network of bridges, offices, residences, and skyscrapers.

4.C. Heating Systems: Heating systems, boilers, and heat exchangers often employ ERW pipes, due to their high tolerance to temperature variations.

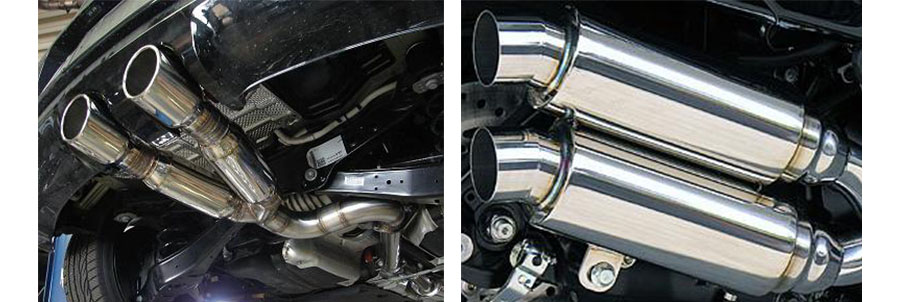

4.E. Automotive Industry: Automobile manufacturing employs ERW pipes for crafting parts due to their strength to weight ratio and corrosion resistance.

4.F. Transport Infrastructure: Railways, airport structures, and seaports utilize ERW pipes due to their high strength, durability, and corrosion resistance.

4.G. Building Structures: ERW pipes lend their durability in crafting robust architectural elements in myriad constructions.

4.H. Public Infrastructures: Public infrastructures like bridges, highways, and machinery require ERW pipes for their durability, strength, and the ability to withstand adverse environmental conditions.

Conclusion: Future of ERW Pipe

Given its array of benefits and widespread usage, ERW Pipe will remain a cornerstone in the industrial sector’s future growth. Though constantly evolving, its foundational strengths form the basis for the development of new variants that suit our rapidly growing society.