leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

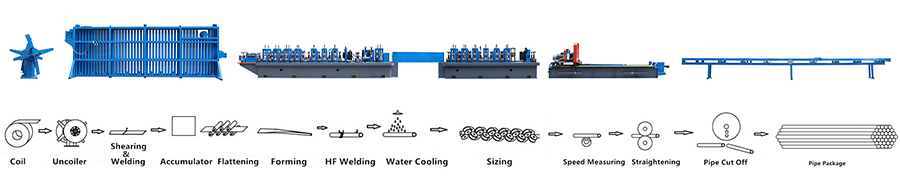

High frequency pipe making machine ,also known as a high-frequency welded tube manufacturing machine or erw tube mill, is an industrial machine used in the manufacturing process of welded steel tubes or pipes. It utilizes high-frequency induction welding technology to produce tubes or pipes from flat steel strips or coils.

Let's talk about the erw pipe manufacturing process:

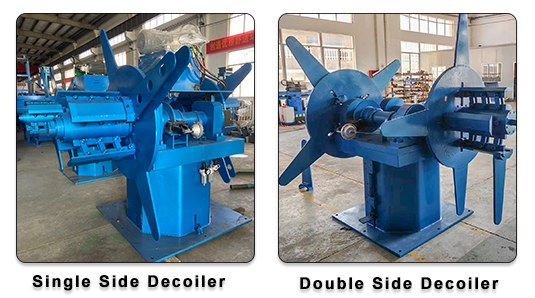

The process begins with uncoiling steel coils or strips that serve as the raw material for the pipes. There are two kinds of decoiler, one is double side decoiler, another is single side decoiler. We will recommend a suitable decoiler based on specific needs.

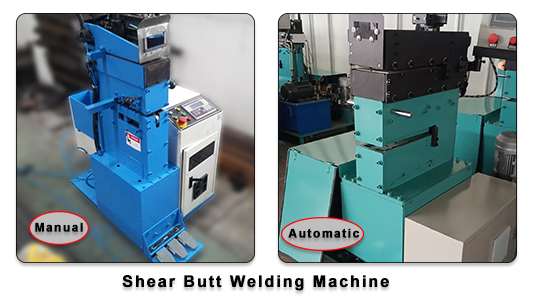

In order to achieve continuous steel strip supply, we will use shear butt welding machines. Input the width and thickness of the steel strip, automatically adjust the current, and realize automatic shearing and butt welding of the beginning and end of the steel strip.

Vertical type or horizontal type cage accumulator for storing steel strips to ensure uninterrupted production.

Pipe forming: The continuous steel strip passes through a series of rollers and forming stands that shape it into a cylindrical tube. The edges are brought together to form a longitudinally welded seam.

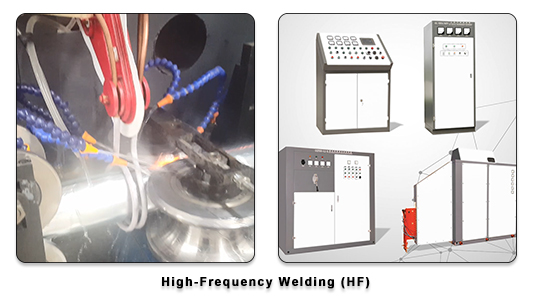

The longitudinally welded seam is heated and fused together using high-frequency electric resistance. An electric current is passed through the edges of the strip, causing them to heat up and form a solid weld. This process typically involves high-frequency induction welding technology to create a strong and durable weld.

External weld treatment: After welding, the steel tube is subjected to external welding seam treatment.

Online zinc supplement: We will reserve a place for online zinc supplementation. If you need to produce galvanized pipes, you need to add zinc online.

Water circulation cooling: The steel tube will then be cooled by water circulation to avoid deformation due to high temperatures.

Sizing and Shaping: The welded tube is then passed through various sizing rolls and shaping stands to achieve the desired dimensions and shape.

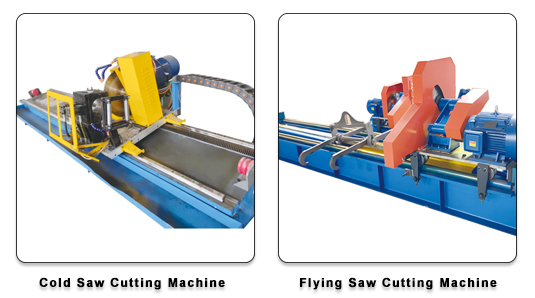

The welded pipe is cut into specific lengths according to customer requirements using the cut-off saw. There are two kinds of cutter, cold saw cutter and hot saw cutter. We will recommend a suitable cutter based on customer needs.

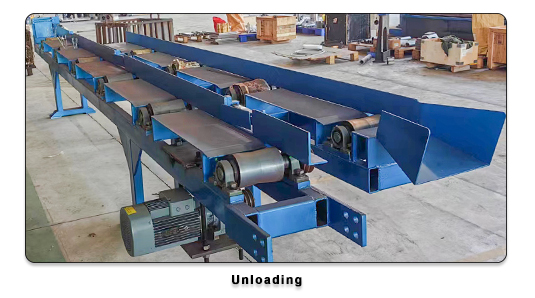

The final steel tubes are collected through the unloading rack.

High frequency pipe making machine can produce carbon steel pipes, galvanized pipes, black iron pipes, etc. It offers advantages such as high production speeds, consistent weld quality, precise sizing, and the ability to work with different steel grades. The finished steel tubes are widely used in scaffolding pipes, greenhouse pipes, steel structures, acoustic pipes, wiring pipes, furniture pipes, etc.