leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

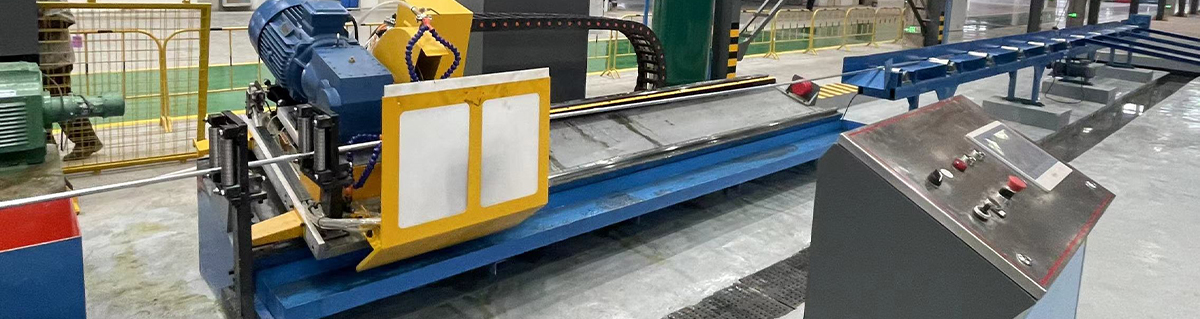

Steel tube mill cut-off machine is an essential piece of equipment in the manufacturing process of tubes and pipes. It is designed to cut continuous lengths of metal tube or pipe into specified lengths as they come out of the tube mill. These machines ensure precision and efficiency in cutting operations, contributing to the overall quality and productivity of the tube manufacturing process.

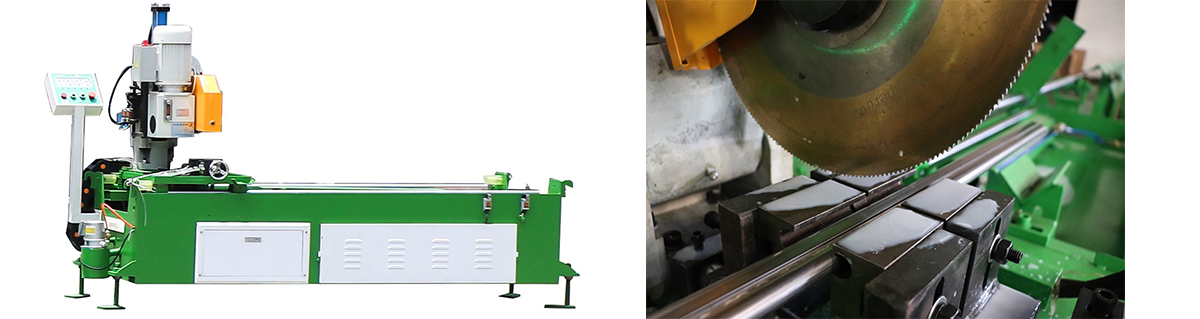

Cold Saw Cut-Off: Uses a circular saw blade to cut the tube. It is suitable for cutting tubes with a clean finish and minimal burr.

Abrasive Cut-Off: Utilizes an abrasive wheel to cut through the tube, suitable for hard materials.

Metal Saw Cut-off: the pipe cut by metal saw cutter ,end of the pipe without the burr.

Laser Cut-Off: Employs laser technology for high-precision cutting, ideal for intricate shapes and profiles.

Belt Saw Cut-off: Suitable for cutting large and thick pipes (above 133mm).

Servo Cutt-off: Can cut short tubes online (length 300mm), equipped with encoder, high cutting accuracy, power saving. PLC control, intelligent.

Automotive Industry: For manufacturing exhaust systems, drive shafts, and structural components.

Construction Industry: Producing pipes for plumbing, scaffolding, and structural support.

Furniture Manufacturing: For creating metal frames and structures.

Aerospace and Defense: Manufacturing precision tubes for aircraft and military equipment.