leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

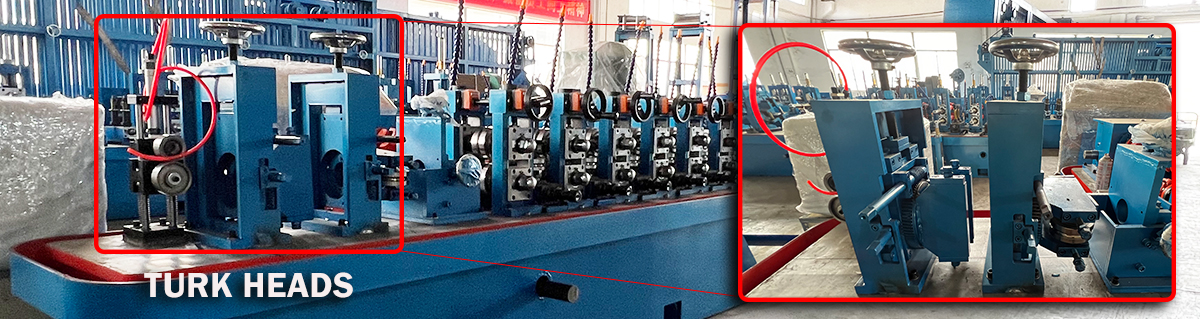

Turk Head is a critical component in tube and pipe mill machines, particularly in the finishing section of these mills. It is used for straightening and sizing tubes and pipes after they have been welded and formed.

The primary function of the Turk Head is to straighten the tube or pipe. During the welding and forming processes, tubes can become slightly bent or misshapen. The Turk Head helps correct these deformations, ensuring that the tube is straight and true.

Besides straightening, the Turk Head is also used for sizing the tube to precise dimensions. This is crucial for meeting the tight tolerances required in many applications, ensuring that the tube or pipe has the correct outer diameter and wall thickness.

The Turk Head removes any surface deformations or irregularities that may have occurred during the welding and forming processes. This is important for improving the aesthetic quality of the tube and ensuring it meets the required specifications.

By ensuring that the tubes and pipes are straight and correctly sized, the Turk Head improves the overall quality of the finished product. This is crucial for meeting industry standards and customer specifications.

The use of a Turk Head increases the efficiency of the production process by reducing the need for additional straightening and sizing operations downstream. This leads to faster production times and reduced costs.

The adjustable nature of the Turk Head allows it to be used for a wide range of tube and pipe sizes, making it a versatile tool in any tube or pipe mill.

The Turk Head is an essential tool in the tube and pipe manufacturing industry, providing critical straightening and sizing functions that ensure the finished product meets stringent quality standards. Its adjustable design and efficiency benefits make it a valuable component in modern tube and pipe mill machines.