leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

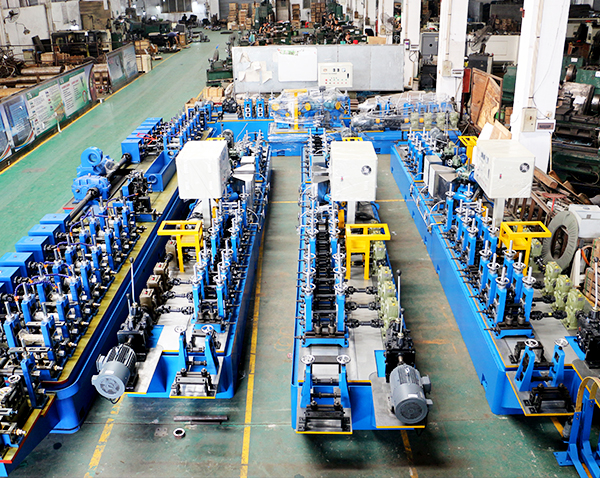

| High frequency tube mill product parameters | |||||

| Machine Model | HF28 | Round Pipe Diameter | 8mm-50.8mm | Square Pipe Diameter | 10mm*10mm-40mm*40mm |

| Round Pipe Thickness | 0.3mm-1.8mm | Square Pipe Thickness | 0.3mm-1.5mm | Production Speed | 20-120m/min |

| Main Motor Power | 90KW | High Frequency Power | 100KW | Material | Q195,Q235,16Mn |

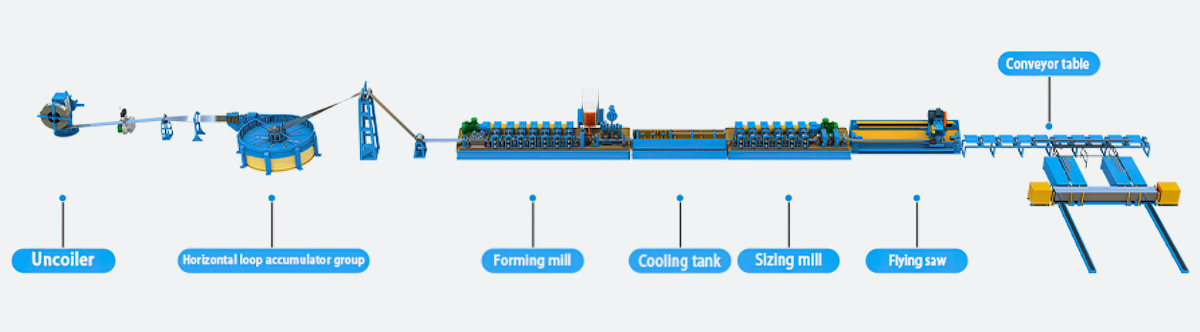

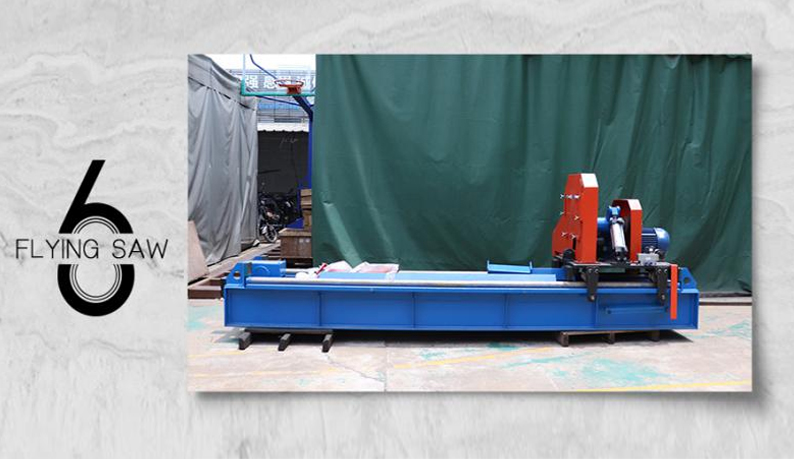

| Machine Configuration | 1.double side uncoiler 2.steel strip cutter 3.vertical type material accumulator 4.forming and sizing machine 5.pipe cutting saw(cold cutting or friction cutting) 6.pipe unloading platform 7.rolling molds 8.high frequency appliances | ||||