leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

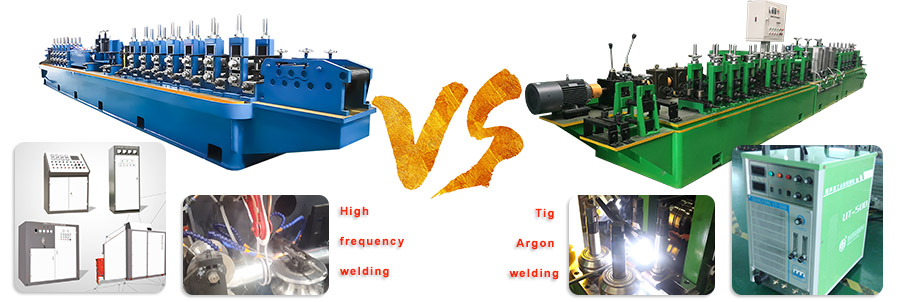

We have two kinds of tube mill, one is high frequency welding tube mill, another is tig argon welding tube mill. Today, let's discuss about high frequency welding vs tig argon welding.

1.High Frequency Welding: Definition and Basics

Concept of High Frequency Welding High frequency welding is an advanced method of fusion welding that uses electromagnetic energy to generate heat and fuse materials together.

2.TIG Argon Welding: Definition and Basics

Concept of TIG Argon Welding TIG argon welding, also known as Gas Tungsten Arc Welding (GTAW), is a process that uses a non-consumable tungsten electrode to deliver a current to the welding arc.

3.Comparison of High Frequency and TIG Argon Welding Methodologies

Technique Approach High frequency welding involves an energy oscillation approach, whereas TIG argon welding is a method that directly utilizes a physical heat source.

Resource Utilization Efficiency Considerations such as time, energy consumption, and input materials also set these techniques apart. High frequency welding generally consumes less energy and performs at a faster rate compared to TIG argon welding.

3.1Benefit Analysis of High Frequency Welding

Speed and Efficiency The primary advantage of high frequency welding is its speed. Due to the nature of the electromagnetic process, welds can be formed quickly and efficiently.

Quality of Weld High frequency welding can also deliver high-quality welds, making it suitable for applications that demand strength and durability.

3.2Benefit Analysis of TIG Argon Welding

Precision TIG argon welding excels in areas of precision, as it allows for greater control over the welding arc and hence, the weld itself.

Versatility It is also extremely versatile, capable of welding a wide range of materials, including copper, aluminum, magnesium, and their alloys.

3.3Limitations of High Frequency Welding

Application Restrictions The high frequency welding process is most effective when working with materials that are highly conductive to electric current. Thus, its use may be limited when dealing with non-conductive materials.

Health and Safety Risks Without proper shielding, high frequency welding can also pose a significant risk of harmful radiation exposure.

3.4Limitations of TIG Argon Welding

Training and Skill Requirement The use of TIG argon welding requires a high level of skill and training. The technique is complex to master and requires a steady hand to ensure a quality weld.

Speed and Efficiency In terms of speed and efficiency, TIG argon welding is often slower than high frequency welding. This is due to the meticulous nature of the process, which lays emphasis on accuracy and precision.

4.Conclusion:

Selection Based on Project Needs Deciding between high frequency welding and TIG argon welding often boils down to the specific requirements of a project. While the former is best suited for operations demanding speed and efficiency, the latter shines in scenarios demanding precise and high-quality welds. Therefore, the selection must be made judiciously, balancing the pros and cons associated with each technique.